Teams:

KCIRI Team and Department of Automobile Engineering

Industry:

Centre for Advanced Systems, DRDO.

Abstract:

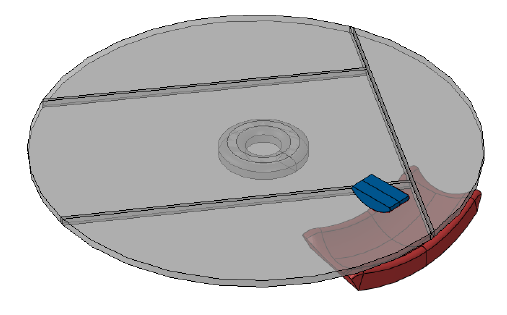

This research involves study, analyze and recommend the most suitable manufacturing process for the dome shroud(torispherical head shape) of a missile canister from amongst a few possible manufacturing methods. A few popular manufacturing process of domes are cold forming and hot forming. In cold forming process, a large plate of circular blank is taken to form the entire dome shroud through multiple punch. Incase of non availability of large plates two or more plates are welded together and made to the dome shroud in shape of torispherical head. Whereas in hot forming, 90deg plate segment is formed at high temperature and those petals are welded together.

The simulation of non linear FE analysis is performed using Abaqus to evaluate the deformations and stress at the time of manufacturing.

Applications:

Simulation of multi press forming

Stress analysis during hot and cold forming process.