Teams:

KCIRI Team and Department of Automobile Engineering

Industry:

Raj Conbuild limited, New Delhi

Abstract:

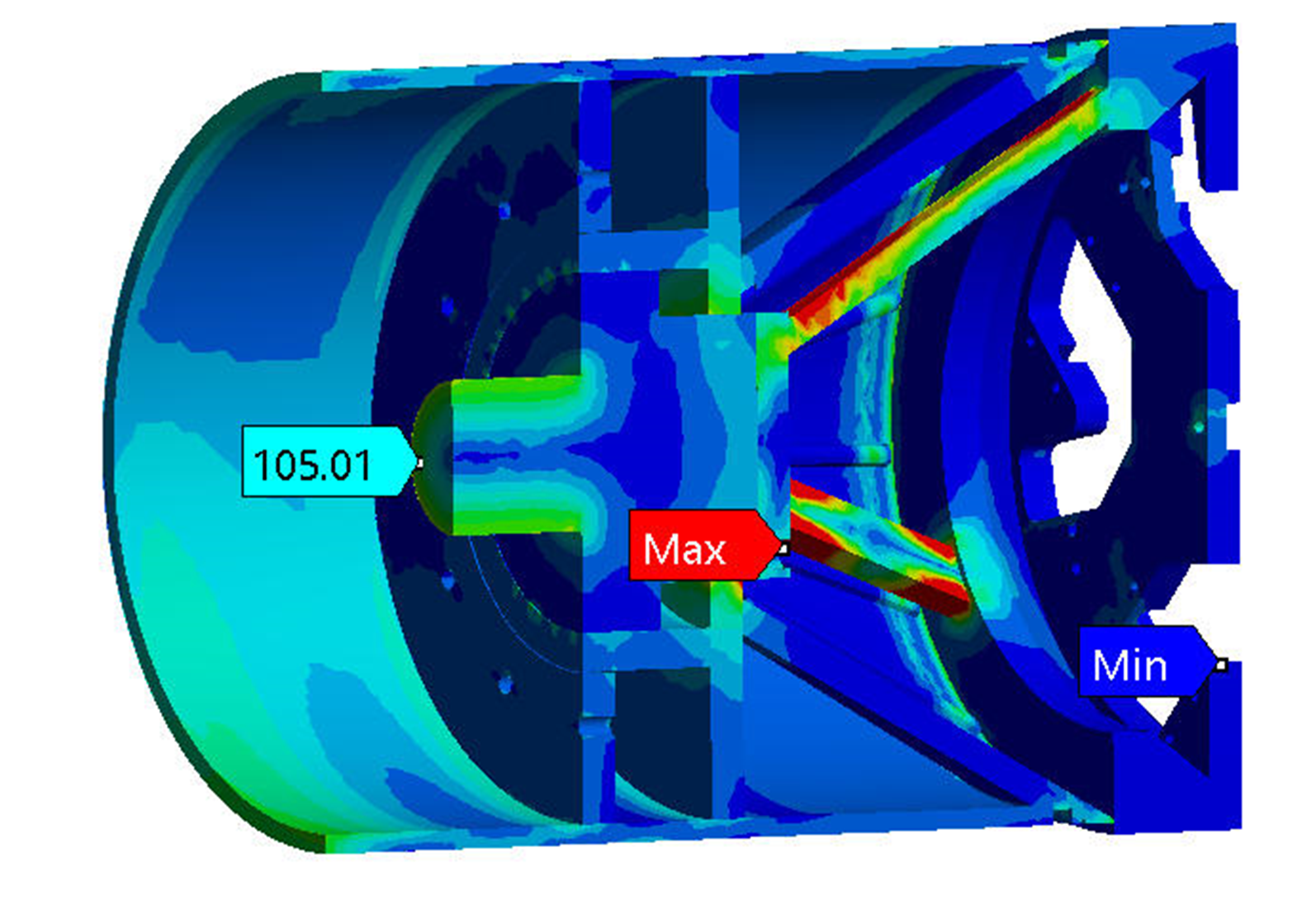

Micro tunnel boring machines (MTBM) are the smaller size of tunnel boring machines for installing pipelines beneath the earth’s surface with minimum disturbance to the regular life of the community above the tunnelling location. The micro tunnelling process is a remotely controlled continuous process to insert the pipes under the ground with the different types of soil and rock conditions using the hydraulic pipe jacking technique. The cutting shield is driven by the shaft that experiences the loads transferred from Earth pressure, water pressure, building loads over the tunnelling locations and seismic loads. Also, the shaft may experience sudden jerks during the restarting of the evacuation process. There are many possibilities of failures of cutting blades, shaft, and bearings during the excavation process. The objective of the project is the calculation of the active & passive loads that are transferring to the shaft and carrying out structural analysis to verify the shaft design. Also, the scope of work includes the selection of suitable bearing for the operation. The accessibility and repair of failures in micro tunnelling are challenging because of the smaller diameter of pipes. Therefore, the shaft is the major driving system that needs to be designed to withstand all the operating loads.

Application:

Underground boring or mining application