Team:

KCIRI Team and Dept of Automobile Engineering

Industry:

DRDL, Hyderabad

Abstract:

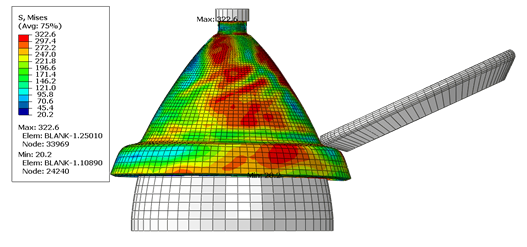

Manufacturing of the axi-symmetric curvilinear shapes like cones, missile nose is challenging and requires highly skilled manpower. To reduce the complexity, failure factor and the wastage of time & cost in realizing these shapes, numerical analysis helps in deciding the process parameters & tools. Metal spinning process and deep drawing process are the general sheet metal manufacturing processes that are used for forming the axi-symmetric metal components from a flat sheet metal without removing the material. The scope of work involves the Non-linear Finite Element Analysis (FEA) of the shear spinning and deep drawing methods to identify the suitable process methodology for forming the ogival shape nose cone. The final product shape and quality depends on the process parameters like sheet metal holding pressure, tools configurations, tool path, corner radii, feed rate, rotational speed, lubrication and tool force. Non-linear FEA results of both the processes with combination of different parameters are performed to conclude suitable process and process parameters based on power required, number of process stages and cost.

Application:

The ogival component under the scope of work is a part of special Armor protection in defence application.